This is a tutorial for creating phone cases for the Samsung Galaxy Note series. The design may differ from phone to phone, but the process is the same. It's important to note that there are thousands of different phone models in the market and because of this, we can't cover every single type of case. With that being said, you should be able to apply these instructions on your own case model with a bit of creative thinking and hard work. The idea behind this guide is to show you how we create a case using a 3D pen and some plastic filament.

1. Tools and materials needed

All you need to get started is a few first aid essentials: bandages, gauze, tape, antibiotic cream, pain reliever, and antiseptic wipes. A 3D printer is most effective when using polyimide. It is a strong, flexible material that has many layers. To print a case on polyimide, you need to first cut out a template of your design. In the photo above, it’s open ended, so let’s just say we have a circular design. Then we need to cut out a rectangle out of the template to use as a template to cut out our polygons. After cutting out our polygons, we need to prepare the polyimide so that it’s stable on the heated bed. Put some pressure on the polyimide while it’s still hard, and it should become very rigid. Then we need to take it off the heat and let it cool. To apply the shrink film, we need to ensure that the polyimide is completely dry before spray painting it. We’ll clean up the sides of the case before we apply the shrink film, and then we’ll spray paint it. Finally, we need to clean up the cut out area so that it’s completely free of any adhesive or spray paint that may have gotten into the case. Congratulations, you’ve completed your level one of the project. The next phase of the project involves printing two cases. Each case will need a name, label, and a QR code on the back. Our first case will be for a white background. In the project, we have this in the layout: the label is A1334 (the number ‘A1334’ is just a location marker that I added during the design stage to save a lot of time when creating an area to store labeled files.) wrapping paper was wrapped around the case, and we placed the label on the phone’s back.

2. Step 1: Designing the phone case

In order to create a phone case, you have to design it first. There are a few free tools online that allow you to create your own phone case designs. Once you have created your design, you can share it with an online store to get it printed. Some of the 3D design software models are available for free, while others require a subscription. Despite the subscription being a little steep, it will only take you a few dollars to print your design. A single piece of plastic filament stretches to about 5 mm, but we added some extra support pieces in order to get our phone case up to the required size. After designing and 3D printing our design, we put it on a piece of cardboard and taped it into place. We now have our 3D printed case shaping completed. It may not look like much now, but when we apply a little plastic pressure to our case, it will start to bulge out more. Now that we have our printed phone case, it feels like cardboard and can take a little pressure. We moved it up to a kitchen table and applied more pressure by sliding it on the table till the bending point is reached. We could probably get it to come out even stiffer by applying extra pressure when it’s printed, but we’re working with what we got. Our phone case is now folded up into a box form factor that looks quite nice with the company logo on it. Here’s a glance at the phone case in all of its glory with the front glass reversed. Here you can see a shot of the printed case with the marked outline. You can clearly appreciate how nice the model looks hand-buffed. Here we are inserting the phone into the case without much support. Now we want to add some protection to our device. We added some spacer pieces between the top of the phone and the top of the case.

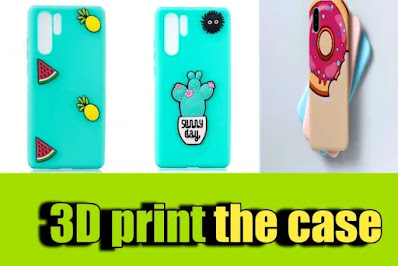

3. Step 2: 3D print the case

3D printing is the process of making a physical object from a 3D model. The 3D printer reads the design file and builds the object layer by layer. With 3D printing, you can make anything from functional prototypes to artistic sculptures. It’s also an inexpensive and efficient way to Start creating your own phone cases. Your 3D computer files will need to be in.STL format. If you’re not familiar with the format, it’s basically a computer-readable file format designed to make file browsing much easier. A 3D designer will be able to open most.STL files and cut them up into objects from which they can make their own design. If you’re new to 3D printing, here is a guide explaining the different 3D printing formats that will help you navigate the confusing world of 3D printing. It should be noted that you may need to click “Proceed as Upload” after downloading your design, otherwise the 3D printer may not be able to build your design. Some 3D printers can have issues with certain CAD models, such as loops and curves. Start by downloading the 3D design I used in the photos below. This file is available here: Samsung_Note_Printing_spec_v1.stl. The dimensions of the print should be centered around 75% of the full phone. This means the height, width, and depth should be 75% of the full phone. I’m not sure why 75%? My theory is 75% of the phone is too thick to print flat, while the other is too thin to print flat, so the phone case is somehow shaped like a flower or a fallen tree. That’s a little weird. Next, we will upload our design. To open the Samsung Note 3 AutoCAD design that we just downloaded: Then go to File > Open and pick Samsung_Note_Printing_spec_v1.3f3. You should see the middle block with the dot in it. Below this, you will see a file selection box. Select this block. Then click Add.

Read More Details: Microsoft Windows 10 Insider Tips And Tricks

4. Step 3: Create a mold using the 3D printed case

3D printing is an additive manufacturing process that turns digital 3D models into physical objects. Unlike traditional manufacturing methods that use molds, 3D printing builds objects up in layers. Each layer is slightly more than one-thousandth of an inch thick. Step 3: Create a mold using the 3D printed casemodel. at a higher temperature than your local Celsius (Centigrade). This allows for the mixture of plastic filaments to harden faster, forming a solid-state mold that adheres to the design inside of the case. To complete this step, separate the two main parts of the case in half, and then completely separate the extruder nozzle from the dowel pin that holds the nozzle inside of the case. Step 1: Begin by printing the outline of your case all the way around. Making sure to leave a bit of space between each side of the curved pieces of your case. Make sure to leave a 2mm gap at each corner, as shown in the picture. Step 2: Now, take the outside of the case (in this case, the buttons and volume rocker) and, using your newly designed 2mm gap, carefully push the wall of the container outward and away. You should end up with a case that looks like this example. Step 3: Now that you are done printing the outside of the case, carefully pour a wide range of coloured plastic filament into the hot end. This will be our primary black material. When the filament warms up, push it out into a flat, clean edge and allow it to cool before moving on to the second material; this material you will pour white plastic filament into. Step 1: repeat step 2 creating the contrasting inner and outer brown material. Step 2: Once the plastic filament has cooled to your liking, carefully remove the case from the printer by carefully prying at the insides of the case to separate it from the nozzle.

5. Step 4: Give your phone case a glossy finish

Give your phone case a glossy finish to add a little pizazz. If you don’t mind a little texture on your case, then gloss it. Otherwise, go with a flat finish. The first thing you’ll need is a 3D printer. I use and adore Makeblock. The price varies based on the size of your case. You can always look up a print/3D shop here or google for the closest store if you’re looking to buy. For this project, I used this printer: A print bed should be no larger than 30 x 28 inches. You should be able to print the case to the size you’ve decided on with some practice. The 3D model I used was a black case model made by editor Amal Graafstra called “Pulse”. With a few edits, I had it transformed into this shiny, sparkly, Note phone case. I’m not going to go over cutting and shaping the plastic for this step. You can visit Makeblock’s website here if you want to learn more about how to get started. While the model was open in 3D, I exported it as a STL file. You can follow this tutorial on how to use the free RenShape software. After exporting the model, I created a couple of reference STLs on Thingiverse. I used a 3D printer with a heated bed, but it should be safe to use any other 3D printer. All models used were made by 3D Think Tank, so feel free to use them as you please. I’m going to explain the basics of using the Z-axis of the 3D printer. This Z-axis is perpendicular to the Z-axis of the printer and allows the material to move up and down along it to move around your model and give it a little bump. If you know what I’m talking about, this will look somewhat familiar.

0 Comments

If you any doubts, please let me know.